- Home

- 产品线

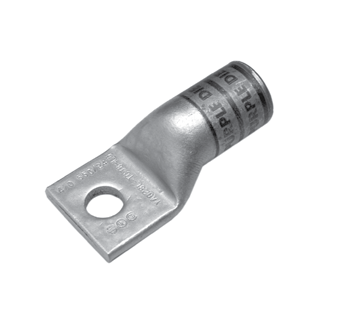

- Compression Lugs

- Standard Lugs

- YAG-L-TC-LD

YAG-L-TC-LD

- General Details

- Features & Benefits

- Related Products

BURNDY奔迪压缩式铜端子由高品质的高导电高纯度电解铜制成,纯度高达99.99%;线径从22AWG到1000平方,定位孔有M3M4M5M6M8M10M12M16等多种选择,可制成45度或90度弯角;标准电镀锡,对于高温环境可选择电镀镍,连续工作温度最高343°C间歇工作温度398°C;奔迪压缩式连接器、压模和压线钳匹配使用可达到行业内高品质要求!符合UL和CSA!

BURNDY® compression connectors are designed for reliable and controllable electrical connections. The complete installation is fully inspectable. They are high conductivity copper and operate cooler than the wire on which they are installed. The connectors withstand a wide range of electrical and environmental conditions, including current surges, temperatures, corrosion and vibrations, for a wide variety of applications. These features mean a consistently high quality connection at a low installed cost.

Copper compression connectors are manufactured from high-conductivity electrolytic copper. The connectors are normally tin-plated, lead plated, or plated with proprietary BURNDY brite finish to provide durable long-lasting corrosion resistance.

The connector design has been matched to the cable size to provide the necessary physical strength requirements for reliable electrical performance.

UL Listed 90° C,600 Volts to 35kV ♦

45° and 90° angles are available.

YAG18TC516LD YAG8CLTC10LD YAG8CLTC14LD

YAG8CLTC516LD YAG8CLTC38LD YAG8CLTC12LD

YAG6CLTC10LD YAG6CLTC14LD YAG6CLTC516LD

YAG6CLTC38LD YAG6CLTC12LD YAG4CLTC10LD

YAG4CLNT10LD YAG4CLTC14LD YAG4CLTC516LD

YAG4CLTC38LD YAG4CLTC12LD YAG2CLTC10LD

YAG2CLTC14LD YAG2CLTC516LD YAG2CLTC12LD

YAG1CLTC10LD YAG1CLTC14LD YAG1CLTC516LD

YAG1CLTC38LD YAG1CLTC12LD YAG25LTC14LD

YAG25LTC516LD YAG25LTC38LD YAG25LTC12LD

YAG26LTC10LD YAG26LTC14LD YAG26LTC516LD

YAG26LTC38LD YAG26LTC12LD YAG26LTC58LD

YAG26LTC34LD YAG27LTC10LD YAG27LTC14LD

YAG27LTC516LD YAG27LTC38LD YAG27LTC12LD

YAG28LTC14LD YAG28LTC516LD YAG28LTC516N66LD

YAG28LTC38LD YAG28LTC12LD YAG28LTC58LD

YAG29LTC516LD YAG29LTC38LD YAG29LTC12LD

YAG29LTC34LD YAG30LTC58LD YAG30LTC34LD

YAG31LTC14LD YAG31LTC516LD YAG31LTC38LD

YAG31LTC12LD YAG31LNT12LD YAG31LTC58LD

YAG31LTC34LD YAG32LTC38LD YAG32LTC12LD

YAG32LTC58LD YAG34LTC516LD YAG34LTC516N66LD

YAG34LNT516N66LD YAG34LTC38LD YAG34LTC12LD

YAG34LTC58LD YAG36LTC12LD YAG36LTC58LD

YAG38LTC516LD YAG38LTC38LD YAG38LTC12LD

YAG38LTC58LD YAG40LTC516LD YAG40LTC38LD

YAG40LTC12LD YAG40LTC58LD YAG44LTC12LD

YAG44LTC58LD

• No inspection window is ideal for more corrosive environments as the barrel

transition is not open

• Barrel is designed with an internal chamfer at the wire entry to ensure smooth

insertion of the wire, preventing possible damaging of the wire strands during

insertion

• Short/Standard length barrel is recommended for installations with limited space

requirements

• 45º and 90º angular lugs are available, please contact Customer Service

• Lead plated for battery connectors or other heavy duty equipment, to reduce the

corrosion from lead/acid batteries

• Connectors are clearly marked with stamping and the barrel color coding

• Connectors accommodating wire sizes #10 – 4/0 AWG accommodate both Flex

and Code Wire. See Tables on each page for specific details