- Home

- 产品线

- Compression Lugs

- Standard Copper Lugs

- UL-CSA方头铜鼻子

UL-CSA方头铜鼻子

- General Details

- Related Products

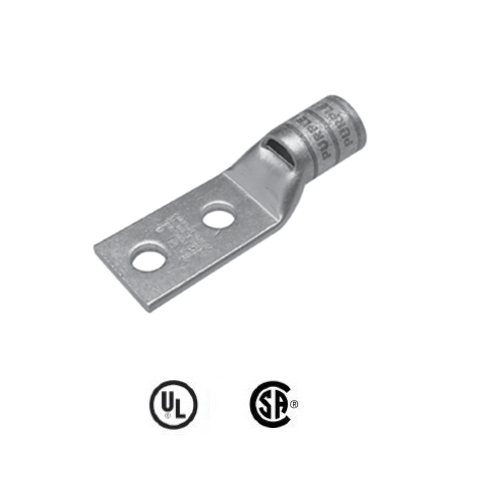

双孔方头管型铜鼻子

符合UL/CSA

BURNDY® compression connectors are designed for reliable and controllable electrical connections. The complete installation is fully inspectable. They are high conductivity copper and operate cooler than the wire on which they are installed. The connectors withstand a wide range of electrical and environmental conditions, including current surges, temperatures, corrosion and vibrations, for a wide variety of applications. These features mean a consistently high quality connection at a low installed cost.

Copper compression connectors are manufactured from high-conductivity electrolytic copper. The connectors are normally tin-plated, lead plated, or plated with proprietary BURNDY brite finish to provide durable long-lasting corrosion resistance.

The connector design has been matched to the cable size to provide the necessary physical strength requirements for reliable electrical performance.

UL Listed 90° C,600 Volts to 35kV ♦

45° and 90° angles are available.

YA8CL2TC10 YA8CL2TC14 YA8CL2TC14E2 YA8CL2TC14E1 YA8CL2TC38 YAV6CL2TC10E9FX

YAV6CL2TC10FX90 YAV6CL2TC10E4FX YAV6CL2TC10E2FX YAV6CL2TC14FX YAV6CL2TC14E2FX YAV6CL2TC14E1FX

YAV6CL2TC516FX YAV6CL2TC38FX YAV6CL2NTCFX YAV4CL2TC14FX YAV4CL2TC14E2FX YAV4CL2TC14E1FX

YAV4CL2TC516FX YAV4CL2TC38FX YAV4CL2NTCFX YAV2CL2TC14FX YAV2CL2TC14E1FX YAV2CL2TC516FX

YAV2CL2TC38FX YAV2CL2NTCFX YAV1CL2TC14FX YAV1CL2TC14E2FX YAV1CL2TC14E1FX YAV1CL2TC516FX

YAV1CL2TC38FX YAV1CL2NTCFX YAV25L2TC14FX YAV25L2TC14E2FX YAV25L2TC516E2FX YAV25L2TC516FX

YAV25L2TC38FX YAV25L2TC12E1FX YAV25L2NTCFX YAV26L2TC14FX YAV26L2TC14E2FX YAV26L2TC516FX YAV26L2TC38FX

YAV26L2TC38E10FX YAV26L2NTCFX YAV27L2TC14FX YAV27L2TC38FX YAV27L2NTCFX YAV28L2TC14E2FX

YAV28L2TC14FX YAV28L2TC516FX YAV28L2TC38FX YAV28L2TC12E1FX YAV28L2TC12FX YAV28L2NTCFX

YAV29L2TC14FX YAV29L2TC14E2FX YAV29L2TC516FX YAV29L2TC38FX YAV29L2TC12E1FX YAV29L2TC12FX

YAV29L2NTCFX YA30L2TC516FXYA30L2TC38FX YA30L2NTCFX YA31L2TC38FX YA31L2TC12FX

YA31L2NTCFX YA32L2TC38FX YA32L2NTCFX YA34L2TC516FX YA34L2TC38FX YA34L2NTC38FX YA34L2TC12FX

YA34L2NTCFX YA36L2TC38FX YA36L2NTCFX YA38L2TC516FX YA38L2TC38FX YA38L2TC12FX

YA38L2NTCFX YA39L2TC38E10FX YA39L2NTCFX YA40L2TC38FX YA40L2NTCFX YA44L2TC38FX

YA44L2TC12FX YA44L2TC12E3FX YA44L2NTCFX YA44L2TC58FX