- Home

- 产品线

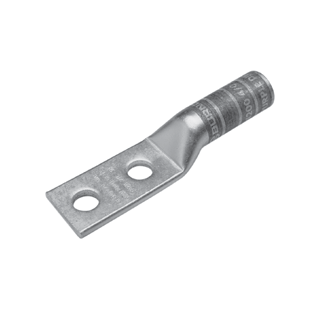

- Compression Lugs

- Long Barrel Lugs

- Terminal Lugs | BURNDY

Terminal Lugs | BURNDY

- General Details

- Video 压接视频

- Related Products

Terminal Lugs UL/CSA

BURNDY奔迪压缩式铜端子由高品质的高导电高纯度电解铜制成,纯度高达99.99%;线径从22AWG到1000平方,定位孔有M3M4M5M6M8M10M12M16等多种选择,可制成45度或90度弯角;标准电镀锡,对于高温环境可选择电镀镍,连续工作温度最高343°C间歇工作温度398°C;奔迪压缩式连接器、压模和压线钳匹配使用可达到行业内高品质要求!符合UL和CSA!

BURNDY® compression connectors are designed for reliable and controllable electrical connections. The complete installation is fully inspectable. They are high conductivity copper and operate cooler than the wire on which they are installed. The connectors withstand a wide range of electrical and environmental conditions, including current surges, temperatures, corrosion and vibrations, for a wide variety of applications. These features mean a consistently high quality connection at a low installed cost. Copper compression connectors are manufactured from high-conductivity electrolytic copper. The connectors are normally tin-plated, lead plated, or plated with proprietary BURNDY brite finish to provide durable long-lasting corrosion resistance.

The connector design has been matched to the cable size to provide the necessary physical strength requirements for reliable electrical performance.

CSA/UL Listed 90°C,600 Volts to 35kV ♦

45°and 90°angles are available.

YA8C2TC14 YA8C2TC14E2 YA8C2TC38 YA6C2TC14 YA6C2TC14E2 YA6C2TC14E1

YA6C2TC38E2 YA6C2TC38E6 YA6C2TC38 YA6C2N YA5C2N YA4C2TC14

YA4C2TC38 YA4C2N YA3C2TC14 W3CRT (2) W3CRT (2) U3CRT

YA3C2TC14E2 YA3C2TC38E2 YA3C2TC38 YA3C2N YA2C2TC14 YA2C2TC14E2

YA2C2TC516E2 YA2C2TC38E2 YA2C2TC38E6 YA2C2TC38 YA2C2NTC38 YA2C2N

YA1C2TC14 YA1C2TC14E2 YA1C2TC38 YA1C2N YA252TC14 YA252TC14E2

YA252TC516 YA252TC38 YA252NTC38 YA252N YA262TC14 YA262TC14E2

YA262TC38 YA262N YA272TC14E2 YA272TC38 YA272N YA282TC14E2

YA282TC38 YA282NTC38 YA282N YA292TC38 YA292N YA292TC58E16

YA302TC38 YA302N YA312TC14E2 YA312TC38 YA312N YA322TC38 YA322N

YA332N YA342TC14E2 YA342TC38 YA342N YA352N YA362TC38

YA372N YA382TC38 YA382N YA392NT38 YA392TC38 YA392N

YA392ENNT YA402N YA412N YA442TC38 YA442N YA452N

YA4532N YA462N YA472N YA482N

PAT46LWL5电动液压钳压线钳500/630/800平方

15-Ton Crimping Tool/ 8 AWG-1500 kcmil Copper, 8 AWG-1250 kcmil Aluminium