- Home

- 产品线

- Compression Lugs

- Narrow Tongue Lugs

- YA-2NT | BURNDY

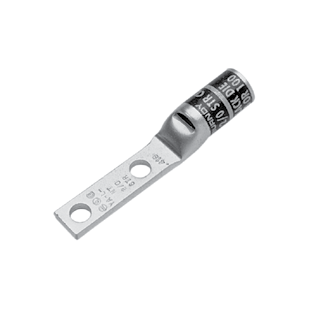

YA-2NT | BURNDY

- General Details

- Features & Benefits

- Related Products

BURNDY® compression connectors are designed for reliable and controllable electrical connections. The complete installation is fully inspectable. They are high conductivity copper and operate cooler than the wire on which they are installed. The connectors withstand a wide range of electrical and environmental conditions, including current surges, temperatures, corrosion and vibrations, for a wide variety of applications. These features mean a consistently high quality connection at a low installed cost.

Copper compression connectors are manufactured from high-conductivity electrolytic copper. The connectors are normally tin-plated, lead plated, or plated with proprietary BURNDY brite finish to provide durable long-lasting corrosion resistance.

The connector design has been matched to the cable size to provide the necessary physical strength requirements for reliable electrical performance.

UL Listed 90° C,600 Volts to 35kV ♦

45° and 90° angles are available.

YA8C2NT8 YA6C2NT8 YA4C2NT10 YA4C2NT14 YA2C2NT14 Y122CMR

YA2C2NT14E2 YA2C2NT14E1 YA1C2NT10 YA1C2NT14 YA1C2NT14E2 YA1C2TC38

YA1C2N YA252NT14 YA252NT14E1 YA252NT38 YA262NT14 YA262NT14E1

YA262NT516 YA262NT38 YA272NT14 YA272NT516 YA272NT38 YA282NT14

YA282NT516 YA282NT38 YA292NT14 YA292NT516 YA292NT38 YA292NT38E16

YA292NNT YA302NT38 YA312NT38 YA312NT38E16 YA322NT38 YA322NNT

YA342NT38 YA342NT38E16 YA342NNT YA342NT58 YA362NT38 YA362NNT

YA362NT12 YA392NT38 YA392NT38E16 YA392NNT YA392ENNT YA392NT58

• No inspection window is ideal for more corrosive environments as the barrel

transition is not open

• Narrow tongue/tang is designed for limited space applications

• Barrel is designed with an internal chamfer at the wire entry to ensure smooth

insertion of the wire, preventing possible damaging of the wire strands during

insertion

• Long barrel allows for an increased number of crimps which will increase the

mechanical strength of the connection

• Two hole tongue/tang is recommended when space permits as the 2-hole

feature minimizes the terminations from loosening or rotating under vibration,

movement, or heat cycling

• 45º and 90º angular lugs are available, please contact Customer Service

• Electro-tin plated unless otherwise specified to reduce galvanic corrosion

(bimetallic) and resist corrosive elements

• Connectors are clearly marked with stamping and barrel color coding