12-Ton dieless 45 angle HYPRESS,6AWG-750kcmil Copper or 6AWG-750kcmil Aluminium

- General Details

- Features and Benefits

- Related Products

The BURNDY® Y46OEM12T is designed specifically for OEM applications. With a variety of bench mounted features, this crimping tool is easy to use and provides the operator a better view of the work going into and out of the crimping tool. The Y46OEM12T is designed to provide 12 tons of crimp force when operated at 8,800 PSI. Using a hydraulic pump set at an output pressure of 8,800 PSI will ensure the 12 tons of output force and will provide maximum life for the tool.

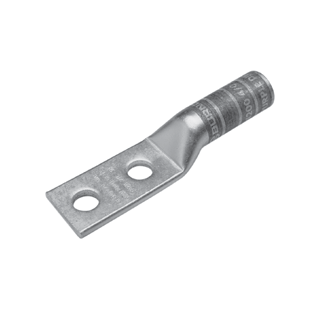

The Y46OEM12T tool uses standard BURNDY® “U” style color coded dies to crimp corresponding color coded lugs for #6 AWG through 750 kcmil Copper (code, flex, extraflex) and Aluminum conductors. The color coded U-Die slides into the PUADP-1 adapter (supplied with the tool) easily with one hand and securely locks into position by way of a spring-loaded, positive-lock, die-retention button. When the Y46OEM12T tool is used in combination with the recommended BURNDY® U-die and connector, the die index number is embossed into the connector and provides for a UL Listed and CSA Certified connection.

This ability to inspect the connection is a feature built into the BURNDY® Engineered System. The picture shown is a Y46OEM12T outfitted with additional accessories (sold separately).

The Y46OEMGUARD accessory is a clear safety shield to help protect the operator from moving parts. The Y46OEMLOCATOR accessory is an adjustable connector stop that allows for consistent crimp alignment. As an added feature, the Y46OEMLOCATOR can be mounted on either side of the tool based on the operator’s preference. The 12TONP1 accessory is a stroke limiter that allows operators to save time when crimping as it restricts the ram from returning all the way after each crimp. This makes repetitive crimping faster.

• Crimp head is mounted at a 45-degree angle to provide visibility to the work area

• Accepts BURNDY® “U” dies for both Copper and Aluminum

• BURNDY® tool, die and connectors are part of the BURNDY® Engineered System allowing for visual inspectability with each crimp – look for the BURNDY® BUG

• Safety, strength and high quality design is assured with this forged steel tool and precision machined components

• Operating tool at 8,800 PSI input pressure increases life of tool and decreases wear

• Accessories available to make crimping safer and faster

• Quality assurance is provided with an audible “pop-off” valve indicating crimp completion